ADHESIVES IN FPC OR PCB

In a flex or rigid-flex PCB construction,many elements have to be considered that can be seen as important to the overall design such as copper weight,layer count,and many other things.However,among all the portions of a design,the one that usually gets forgotten is what bonds and holds it all together,the adhesives and pre-pregs that serve to bond the stack-up.

In flexible PCB stack-ups,adhesives play a core part,where only the extreme and rare instances of a stack-up contain no adhesives.While in rigid-flex designs,adhesives are used in flexible portions,while also using prepregs to bond in the rigid portions and to keep the layers together.

What Are Adhesives?

In flexible circuits,adhesives are nearly the most critical part of any stack-up.While some stack-ups can exist without adhesives,it would be difficult to operate without any.From the coverlay,to the stiffeners,to extra pressure adhesives applied to the exterior of the circuit board,and even to adhesive-based cores,adhesives play a major role in forming the stack-up of a flexible circuit.

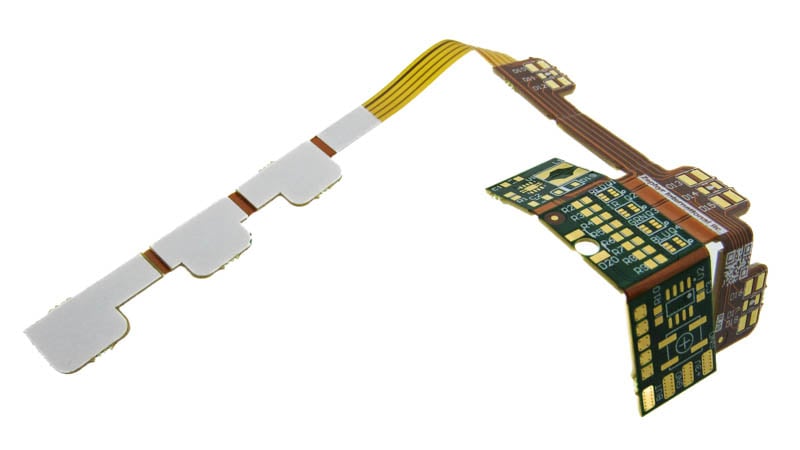

Rigid-flex PCB with pressure sensitive adhesive.

When it comes to adhesives for a flexible circuit,they usually come in three different varieties.

The first are acrylic adhesives.These are versatile adhesives and have proven to be among the most used adhesives in many offshore manufacturing locations.

Next are epoxy adhesives.These are less commonly seen than acrylic,however they serve a purpose in that they can be less reactive to some chemical environments than acrylic can be.The downside is that due to the nature of epoxy adhesives,they can sometimes be regarded as slightly stiffer than acrylic adhesives,and the lower demand can mean increases in cost or lead times depending on materials used.

The last of the three adhesives are polyimide-based adhesives.These can withstand higher temperatures than the previous two and they're highly chemical resistant.The downside is that the demand is so low for this adhesive that many PCB manufacturers cannot support them,and that aside from low demand,the process to manufacture them requires specialty lamination procedures that go beyond what many circuit board fabrication shops can perform.

Adhesives In Rigid-Flex Circuits

In rigid-flex circuits,the role of normal adhesives remains the

same,due to the flexible portion of the part.However,this changes when

thinking of the rigid section,where adhesives are recommended to be

removed.This recommendation comes from IPC guidelines,suggesting that

due to the differing coefficient of thermal expansion of the rigid

materials and flexible materials,it is best to make sure no adhesives

extend into the rigid section where a through hole would travel through

it.

This can be quite a limiting factor,leading to innovations that

allow for multi-layer flexible sections within rigid-flex PCB designs to

be bonded in some sections with adhesives,whereas in the rigid portions

of the stack-up,they are bonded with a near equivalent thickness of

prepreg.This allows a circumvention to include adhesives in rigid

stack-ups and results in a more reliable build.

As for what

prepregs are used,the main restriction is that prepreg's must be what's

referred to as ''no-flow'' or,depending on manufacturer

definition,sometimes referred to as ''low-flow''.These terms refer to

the propensity of the prepreg to flow during lamination processes,where

it is most desired in a rigid-flex PCB stack-up for the prepreg to

exhibit little to almost no flow characteristics,to now flow out into

the flexible section and interfere with the bending capability of

it.These types of prepregs are achieved by taking the standard

formulation and changing it with the addition of a polymer and,in some

cases,by inducing a form of pre-lamination with the manufacturer that

can reduce the flow characteristics of the selected prepreg

dramatically.

Summary

Bonding within rigid-flex PCBs and flexible circuit board applications

can be quite a complicated process.While the terminology can be

unexpected,and the different adhesives to be difficult to remember,it is

always important to remember what the application the part is meant for

and the environment it is set to be in.

This is the single most

important factor and can heavily influence the material choice when

designing the circuit board.While this can sound like a daunting

task,involving the circuit board manufacturer from the start can greatly

help in deciding how to approach the stack-up to a design,what

materials should be used,and which materials they can support.

Please login and click here to download the PDF file: